NEXiS® CS3G-C系列挤出控制器

Features

- Provide PI control of insulation thickness on wire and cable insulation extrusion lines.

- Controls insulation extruders or capstan drives.

- May be used in other diameter-controlled extrusion processes.

- Integrates seamlessly with Proton Products InteliSENS® SL and SLR Series Speed and Length Gauges for line speed measurement.

- Integrates seamlessly with one or two Proton Products InteliSENS® DG and DG-k series diameter gauges for insulation diameter measurement.

- Single DG / DG-k gauge variant for diameter control (D variant) from either hot or cold measured diameter.

- Double DG/ DG-k gauge variants available for automatic shrinkage compensation (HC – Hot-Cold variant) control.

- Independent setting of tolerances, shrinkage, alarm functions and speed input.

- Large, high-resolution, back-lit, colour LCD screen with resistive touch panel.

- Product recipe presets for fast re-configuration between different product runs.

- Password protection (with different user privileges) for changes to settings and product recipe presets.

- SSFD (Single Scan Flaw Detection) for detection of insulation lump and neck flaws.

- Housed in a rack-mountable enclosure (optional stand-alone mounting case is available).

Introduction

The Proton Products NEXiS® CS3G-C Series of controllers are for use on wire insulation or other extrusion production lines.

NEXiS® CS3G-C Series controllers connect to Proton Products diameter gauges and speed and length gauges for measurement of insulation diameter and line speed respectively. These measurements are then fed into a PI feedback controller whose fully-isolated and floating output may be used to drive insulation extruders or capstan drives.

Insulation diameter is thus actively controlled and kept in tolerance by the NEXiS® CS3G-C controller.

NEXiS® CS3G-C Series controllers also have advanced features such as a large, high-resolution colour LCD screen with resistive touch panel, password protection, product recipe presets, and Single Scan Flaw Detection (SSFD, for detection of insulation lump and neck flaws).

Variants

| 变量 | 控制算法 |

|---|---|

| NEXiS® CS3G-C-D | 直径控制 |

| NEXiS® CS3G-C-HC | 热-冷收缩自动补偿控制 |

Insulation Diameter Control Cold diameter only (single DG / DG-k gauge – CS3G-C-D variant)

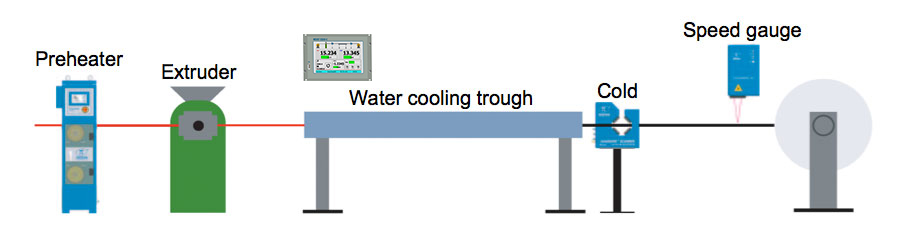

The NEXiS® CS3G-C is connected to the Cold DG / DG-k diameter gauge after the water cooling trough. The Cold diameter measurement is used to control the extruder so that the final insulation diameter is held within tolerance. Since the Cold diameter measurement is located far from the extruder, this control system response time is relatively slow (and dependent on the line speed), but the controlled diameter is the final product diameter.

Hot diameter only (single DG / DG-k gauge – CS3G-C-D variant)

The NEXiS® CS3G-C is connected to the Hot DG / DG-k diameter gauge before the water cooling trough. A shrinkage offset due to cooling is set by the operator and used in conjunction with the Hot diameter measurement to control the extruder so that the final insulation diameter is held within tolerance. Since the Hot diameter measurement is located close to the extruder, this control system response time is relatively fast.

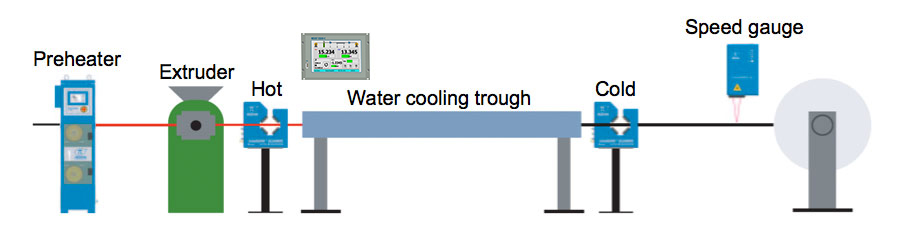

Hot and Cold diameters (two DG / DG-k gauges – CS3G-C-HC variant)

The NEXiS® CS3G-C is connected to the Hot and Cold DG / DG-k diameter gauges before and after the water cooling trough respectively. The shrinkage offset due to cooling is automatically calculated from the Hot and Cold diameter measurements and used in conjunction with the Hot diameter to control the extruder so that the final insulation diameter is held within tolerance. Since the Hot diameter measurement is located close to the extruder, this control system response time is relatively fast and the user does not need to estimate a shrinkage offset.

Specifications

| 显示屏 | 800×480背光彩色液晶显示器,电阻式触摸屏。 | |||||

| 串行通信 | RS232 | USB | CANbus - (最多可连接2个DG系列测径仪) | |||

| 线速度输入 | 模拟 | 两个输入可用于0至10V和0至50V模拟线速度信号;终端用户自行定标。 | ||||

| 脉冲 | 两个输入可用于0至3V和0至10V脉冲线速度信号;最大频率250千赫;终端用户自行定标。 | |||||

| 4×继电器触点输出 | 功能(终端用户配置) | 测径仪OK | SSFD探测到的缺陷 | X或Y轴超容差上限 | X或Y轴超容差下限 | |

| X轴超容差上限 | X轴超容差下限 | Y轴超容差上限 | Y轴超容差下限 | |||

| 电气 | 最高电压 | 50VDC / 30VAC | ||||

| 最大电流 | 500mA | |||||

| 导通电阻(@ 100mA) | < 0.1Ω | |||||

| 断开电阻 | > 10 MΩ | |||||

| 模拟输出1 | 功能(终端用户配置) | ØX | ØXY | |||

| Electrical | 输出电压范围 | 0V to +10V | ||||

| 最大电流 | 2mA | |||||

| 分辨率 | 16-bit | |||||

| 输出电压由终端用户自行定标。 | ||||||

| 模拟输出2 | 功能(终端用户配置) | ØY | 平均误差 | |||

| 电气 | 输出电压范围 | ØY: 0V to +10V | ||||

| 平均误差: -10V~+10V | ||||||

| 最大电流 | 2mA | |||||

| 分辨率 | 16-bit | |||||

| 输出电压由终端用户自行定标。 | ||||||

| 控制算法 | 先进的控制算法(ACA) | |||||

| SPC | 图解直方图 | Cp | Cpk | |||

| SPC 控制 | 统计过程控制:最大限度减少绝缘材料消耗同时保持绝缘直径公差。 | |||||

| FFT | 快速傅立叶变换:显示振幅与周期性直径变化频率的关系。 | |||||

| SSFD | 单扫描缺陷检测:探测包块和瓶颈缺陷。 | |||||

| 预设值 | 标称直径 | +容差 | -容差 | +缺陷(包块) | -缺陷(瓶颈) | |

| 产品配方 | 可将50组产品预设存储在内存中,便于快速调用。 | |||||

| 统计 | 平均直径 | 标准偏差(σ) | 最大直径 | 最小直径 | ||

| 技术规范 | 最小值 | 典型值 | 最大值 | 单位 |

|---|---|---|---|---|

| 重量 | 2.5 | kg | ||

| 5.5 | lb | |||

| 长度 | 231 | mm | ||

| 9.1 | 英寸 | |||

| 宽度 | 213.1 | mm | ||

| 8.4 | 英寸 | |||

| 高度 | 128.5 | mm | ||

| 5.1 | 英寸 | |||

| 电源电压(均方根) | 85 | 264 | VAC | |

| 电源频率 | 47 | 65 | Hz | |

| 电源电流(均方根) | 2.5 | A | ||

| 耗电 | 110 | W | ||

| 环境温度 | 5 | 45 | °C | |

| 41 | 113 | °F | ||

| 相对湿度 @ 38℃/105℉ | 90 | % | ||

| 防护级别(IP) | IP50 | - | ||

| PI控制器输出电压 | -10 | 10 | V | |

| PI控制器输出电流 | 10 | mA | ||

| PI控制器输出电阻 | 10 | Ω | ||

| PI控制器分辨率 | 12 | bit |